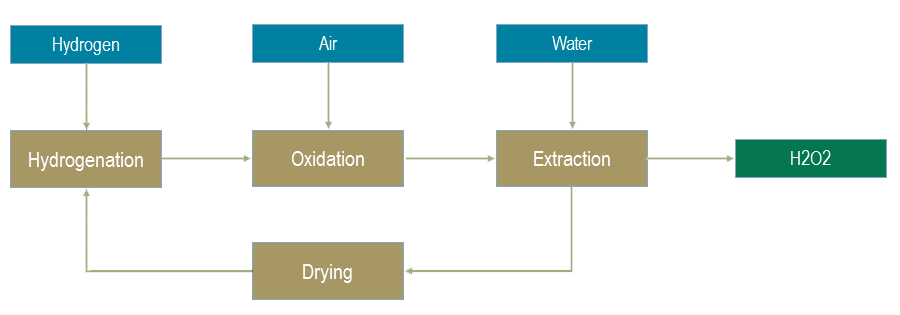

Chematur offers plants to produce hydrogen peroxide by the well-known anthraquinone process. Our technology is state of the art with high yield, capacity and quality. The overall hydrogen peroxide process is schematically shown in the figure above.

The working solution (WS), containing a substituted anthraquinone dissolved in a mixture of solvents, is first hydrogenated in the presence of a catalyst to the corresponding anthrahydroquinone. The next step is to oxidize the anthrahydroquinone by passing air through the WS to regain the anthraquinone at the same time as hydrogen peroxide is produced. The product is extracted from the WS by contacting it with demineralized water to give crude H2O2 which is purified to reduce organic contaminants.

The 30-35 % hydrogen peroxide produced can be distilled to give higher strength H2O2, 50-70% by weight. After drying, the WS is returned to the hydrogenation step to close the loop. To control the build-up of organic contaminants in the WS it is passed through a regeneration column at regular intervals.

Chematur is one of very few technology providers that license the hydrogen peroxide technology to third parties without any demand for control of the production or the market. Chematur has a long experience in supplying advanced processes to third parties worldwide, including the Middle East, India and the Far East. Our typical scope of supply is License, Basic Engineering and Key equipment. With this scope we are giving process guarantees regarding, capacity, quality and operating cost.