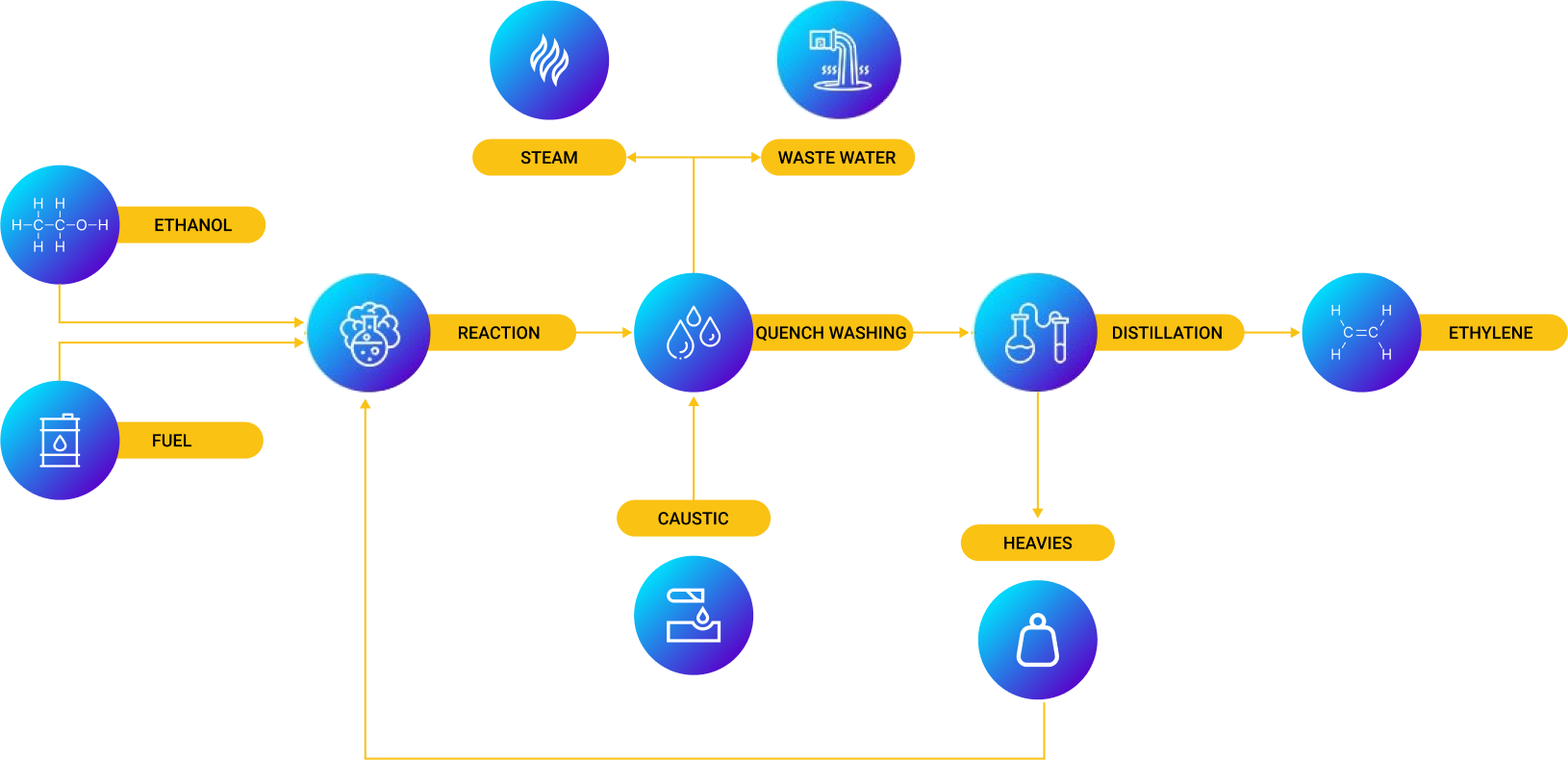

The bio ethylene process starts with bioethanol (95%) which is heated and dehydrated in a fixed bed reactor using Syndol® catalyst. The process is endothermic so the reactor is split into several sections with reheating of the process stream between the adiabatic stages. The catalyst is very selective, reaching approximately 97 % at 99 % conversion. The crude product is quenched and washed with caustic before it is dried and distilled to yield polymeric grade bio ethylene. Lower grades of ethylene can be produced with a somewhat simplified work-up scheme. The catalyst is long lasting with an expected lifetime of minimum two years without need for regeneration.

Ethylene is raw material for PVC, polyethylene, ethylene oxide etc.