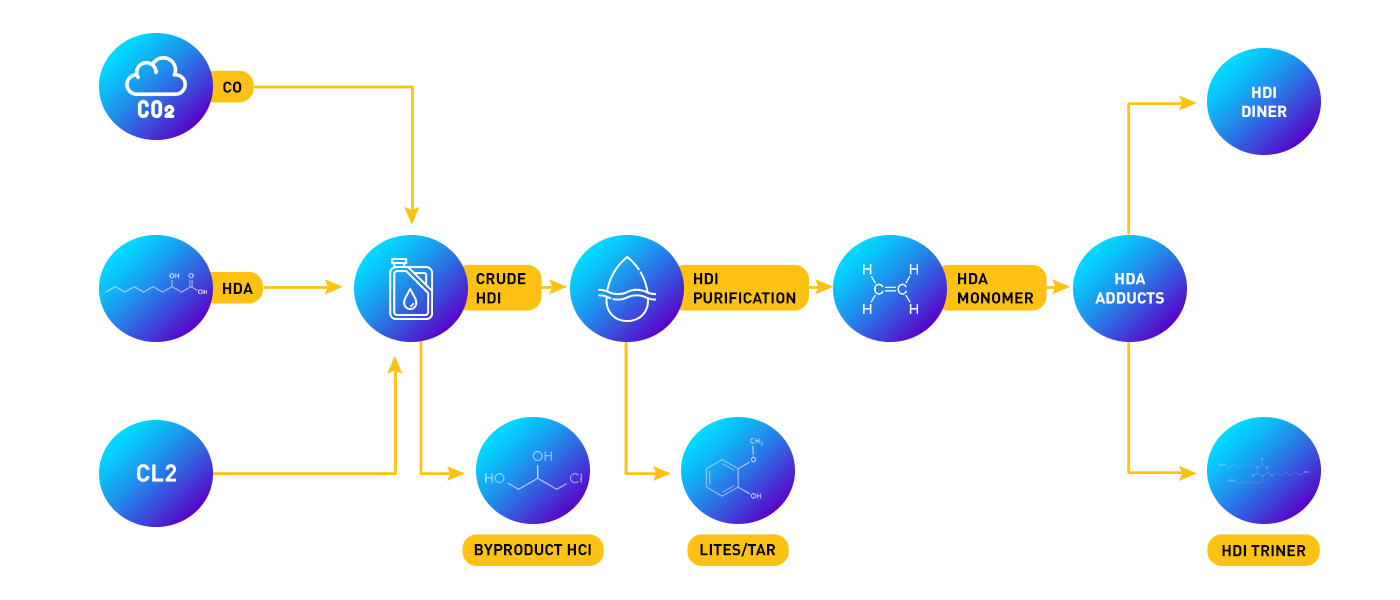

In the aliphatic isocyanates (ADI) field, the main product is Hexamethylene diisocyanate, (HDI, CAS No. 822-06-0) which is produced by phosgenation of Hexamethylene diamine (HMA, CAS No. 124-09-4) but also Isophorone diisocyanate (IPDI, CAS No. 4098-71-9) can be produced in an analogous process from the diamine, Isophorone diamine (IPDA, CAS no 2855-13-2).

"IBIC together with CEAB" can offer technologies to produce aliphatic diisocyanates from the corresponding diamine.

ADI:s are skin and respiratory tract irritants and may cause sensitization upon repeated exposure. That is the reason why Aliphatic isocyanates often are further processed to adducts of e.g. dimer, trimer, or biuret type to make them hazardous to handle. The HDI adducts have CAS No. 28182-81-2 and the corresponding IPDI adducts have CAS No. 53880-05-0. ADI:s are used in high end polyurethane formulations where light stability is of importance, mainly coatings but also in the adhesives, sealants and elastomer field.

In the polyurethane applications the main HDI adduct is the trimer (HT). HT is produced in a continuous process. Other HDI adducts are the biuret (HB) and the dimer (HD). They are both produced in a batch process. Excess HDI monomer is distilled off from the product mixture and recycled. The adducts are sold either neat or mixed with a solvent.