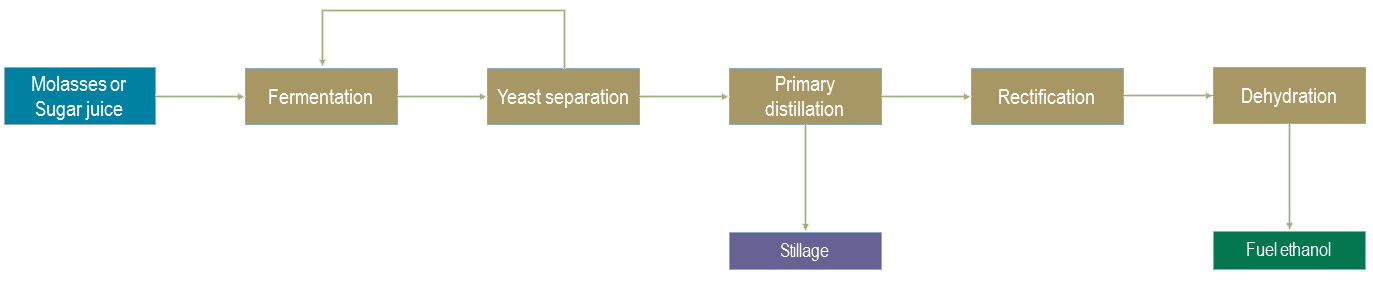

The Biostil® fermentation concept is a unique continuous ethanol process which has been marketed by Chematur since the 1980´s One unique feature of the Chematur Biostil process is that one single fermenter is operated at steady-state with continuous addition of the sugar containing substrate and continuous removal of the ethanol that has been produced. This means that the fermenter is operated at close to zero sugar and medium ethanol concentration only. This together with continuous return of yeast to the fermenter will give a very high productivity and excellent quality with minimum production of fusel oils. Some of the best potable alcohol in the world is produced by the Biostil® process. The fermenter volume needed for a certain capacity is typically only half of what is required with other processes.The figure above shows the heart of the Biostil® process; the yeast recycle, the integrated mash column with continuous distilling off of the ethanol, return of weak beer and removal of non-fermentables as stillage.

Biostil® sugar

The Biostil process was originally developed to ferment molasses, a substrate regarded as very difficult as it contains a high content of inorganic salts which cannot be tolerated by the yeast, especially at high sugar and/or ethanol concentration in the fermenter. Traditional technologies must therefore be operated rather diluted and thus gives a fermentation residue (stillage) after removal of the ethanol which is dilute and smelly.

The Biostil process is operated at optimum condition with high yeast concentration, low sugar and low ethanol content in the fermenter. This together with the use of a special yeast, Schizosaccharomyces pombe, which tolerates high osmotic pressure, a very high concentration of non-fermentables in the fermenter can be tolerated. This in turn gives a very high dry solids content in the stillage and it can be directly recycled as nutrient to the sugar cane or sugar beet field without odor problem. Due to the high concentration employed in the Biostil process, less water is used.

Biostil® starch

The Biostil starch process converts starch containing raw materials to a concentrated sugar solution by enzymatic liquefaction and saccharification. The sugar solution is continuously fed to the fermenter where it is immediately converted into ethanol. Non-soluble fibers are filtered off and sent to the bottom of the mash column. The yeast is recycled to the fermenter before the alcohol is stripped off and the weak beer returned to the fermenter.

By this method a low concentration of sugar is kept in the fermenter at the same time as the ethanol concentration is kept at a stable and relatively low level. This together with the high yeast concentration enables a very high productivity per unit fermenter volume. Furthermore the weak beer sent back to the fermenter has been pasteurized which, together with the low sugar concentration in the fermenter makes bacterial infections much less likely.