The ethanol industry is increasingly playing a significant role in the industry’s landscape as countries are reducing their dependence on fossil fuels and exploring alternate clean sources of energy. Besides its traditional usage as an industrial solvent, effective disinfectant and for potable alcohol, ethanol has seen a major surge in demand since countries have begun necessitating blending it with fuel for automotive applications.

The Indian government has recently announced various policies to boost ethanol production and ethanol blending with a outlook for larger blends over the coming years. Given the prevalence of the sugar industry in India, these new policies are likely to largely benefit in optimal usage of their feedstock.

The Biostil 2000 technology for manufacturing Ethanol offered by us is an upgraded version of the widely popular Biostil technology based on which many distilleries in India yet operate. The Biostil 2000 technology allows for significantly lower volumes of stillage and continuous operation to boost ethanol production.

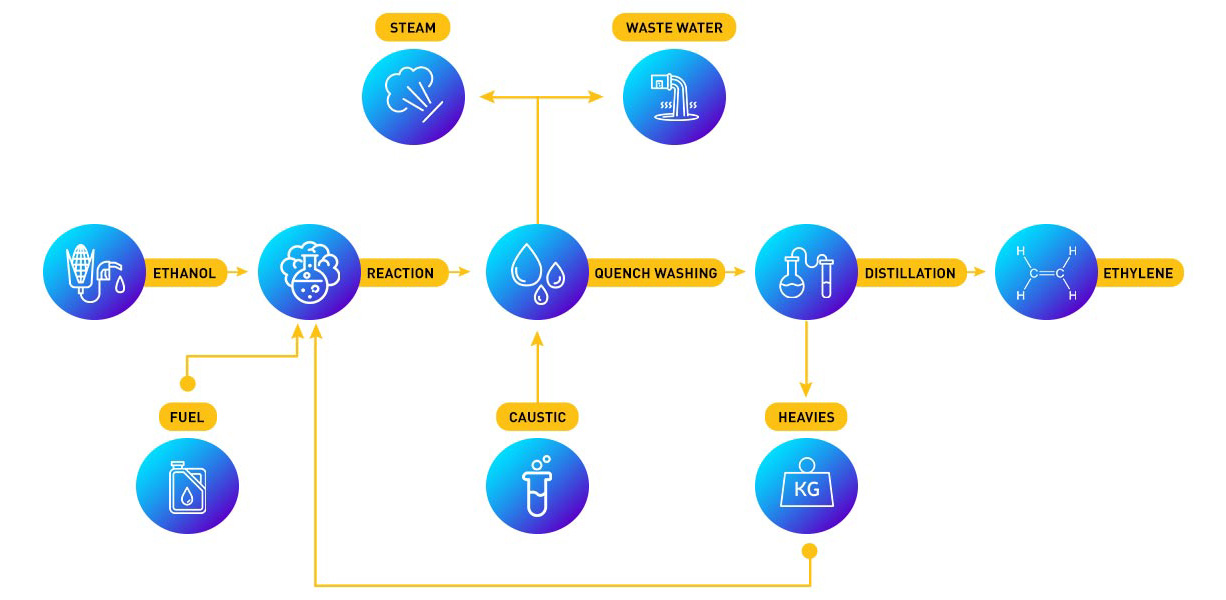

The bio ethylene process starts with bioethanol (95%) which is heated and dehydrated in a fixed bed reactor using Syndol® catalyst. The process is endothermic so the reactor is split into several sections with reheating of the process stream between the adiabatic stages. The catalyst is very selective, reaching approximately 97% at 99% conversion. The crude product is quenched and washed with caustic soda before it is dried and distilled to yield polymeric grade bio ethylene. Lower grades of ethylene can be produced with a somewhat simplified work-up scheme. The catalyst is long lasting with an expected lifetime of minimum two years without need for regeneration.

Ethylene is raw material for PVC, polyethylene, ethylene oxide etc.