Supercritical Carbon Dioxide Technology (scCO2)

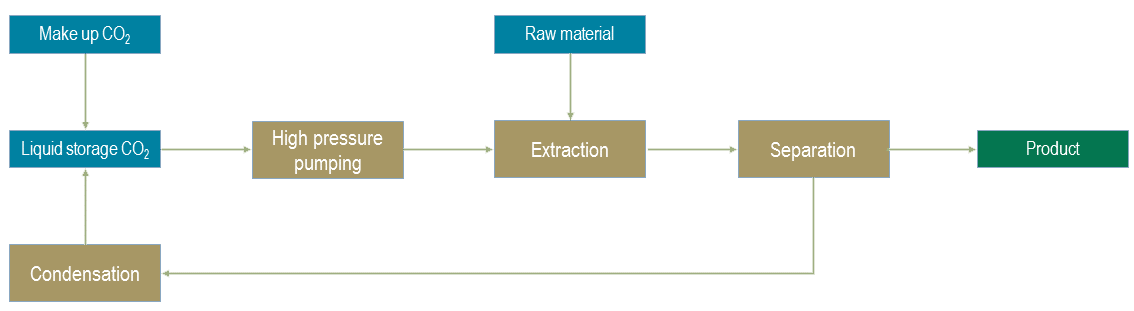

Supercritical Carbon Dioxide Technology scCO2 utilises carbon dioxide in its supercritical state as a powerful, cheap, non-toxic and environmental friendly solvent to carry out a number of different tasks. This can range from extraction of desired or undesired substances in a compound, e.g. a natural product, to its use as a solvent to carry out continuous reactions in an efficient and selective manner. One special application is the Rotowasher™ for precision parts cleaning (degreasing) as an alternative to hazardous chlorinated solvents.

Supercritical Carbon Dioxide Processing

Supercritical carbon dioxide (scCO2) extraction technology has been developing since the early seventies. Large scale applications are found in the field of natural products such as extraction of hops for beer manufacturing and decaffeination of coffee beans. scCO2 as a solvent has several advantages. It is naturally occurring, inexpensive, colourless, odourless, tasteless, non-flammable, non-ozone depleting and non-toxic. In addition it has gaseous like diffusivity and viscosity and complete miscibility with gases. It is one of few solvents that can be unrestrictedly used for food processing.

Supercritical Carbon Dioxide Technology Applications

The market for scCO2 can be divided into different areas with varying degree of maturity according to the listing below.

- Extraction processes with isobaric product recovery.

- Extraction processes with product recovery by pressure reduction

- Degreasing

- Debinding in Powder Injection Molding (PIM)

- Particle formation/antisolvent processes

- Chromatography processes.

- Textile dyeing

- Reactions

- Plastics foaming agent instead of conventional freon.

SuperDebind™, binder removal from injection moulded components.

The SuperDebind™ utilises supercritical fluid extraction to remove binders from injection moulded components. The working principle is dissolving the binders in supercritical carbon dioxide and thereby removing them from the components. This environmentally friendly solution also reduces debinding time compared to conventional methods. All parts are made of stainless steel. Fully automated operation. Compact design.